The most common sources of error in HACCP documentation and how to avoid them

HACCP documentation is an essential part of any food company that wants to ensure the safety and quality of its products. Nevertheless, errors often occur in practice that can impair the effectiveness of the HACCP system. In this article, we highlight the most common sources of error, categorize them according to their relevance and show strategies for eliminating them.

Why precise HACCP documentation is crucial

The HACCP documentation is far more than a mere formality. It plays a central role in ensuring food safety. If documentation is incomplete or incorrect, this can have serious consequences, including recalls, economic losses or legal sanctions.

Source of error: Inadequate employee training

One of the main causes of errors in HACCP documentation is a lack of knowledge or insufficient employee training. Those who do not know the importance of documentation often record processes incompletely or incorrectly.

This error can be rectified in this way:

Regular training and awareness-raising measures are essential. In addition, clear instructions and checklists help employees to carry out their tasks correctly.

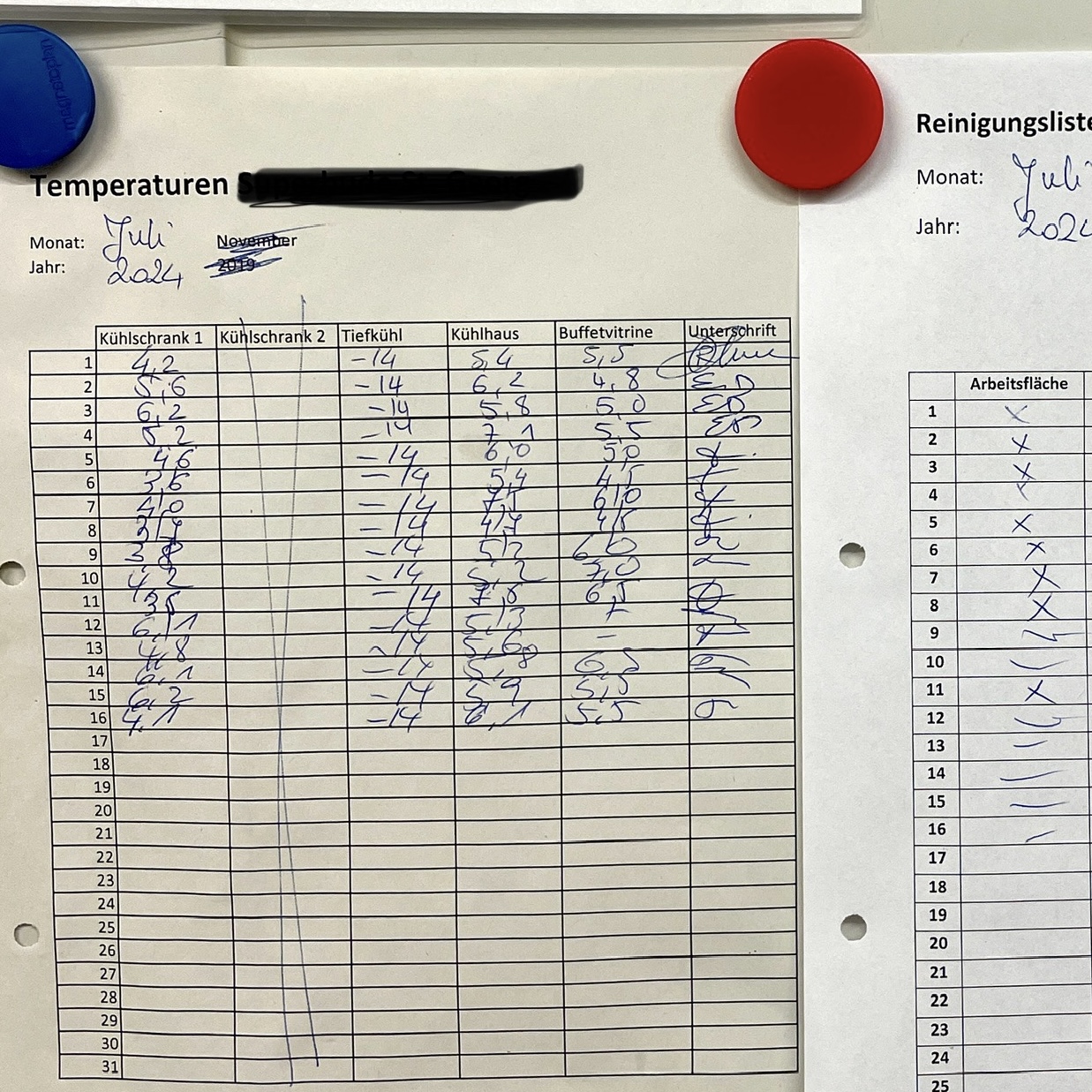

Source of error: Incomplete or inaccurate documentation

Another common mistake is incomplete or incorrect HACCP documentation. If important details are missing, the traceability and verification of processes becomes more difficult.

This error can thus be avoided:

Standardized work instructions create clear guidelines. In addition, regular audits ensure that all documents are kept completely and correctly.

Source of error: Outdated documentation

HACCP documents must be continuously updated. Otherwise, the risk of safety gaps increases as changes are not recorded correctly.

Optimal procedure:

A defined review and update cycle ensures that all documents remain up-to-date. At the same time, all relevant employees have access to the latest versions.

Source of error: Missing or insufficient control

If the HACCP documentation is not checked regularly, errors remain undetected. As a result, problems can accumulate over time and jeopardize the entire system.

Solution:

Internal audits and control mechanisms should be firmly integrated into the company’s processes. It also makes sense for a second person to check the documentation in order to identify possible errors.

Source of error: Unstructured filing and archiving

Poor organization often means that important documents cannot be found. This becomes particularly problematic during inspections or product recalls.

Improvement:

A sophisticated archiving system with clearly defined access rules ensures structured filing. This means that relevant documents can be found quickly and easily.

Source of error: Insufficient adaptation to new processes

HACCP documentation is often not updated in good time when new products or processes are introduced. This results in safety risks.

Recommended measures:

Every change should be immediately incorporated into the HACCP documentation. This step should therefore be firmly integrated into the company’s internal change management system.

Ranking of the most common sources of error in HACCP documentation

- Insufficient training of employees

- Incomplete or incorrect documentation

- Lack of updating of documents

- Missing or insufficient control

- Unstructured filing and archiving

- Insufficient adaptation to new processes

Conclusion: Optimized HACCP documentation ensures the company’s success

HACCP documentation is a decisive factor for food safety. Targeted training, regular checks and a structured organization can prevent errors and increase the efficiency of the system.

Our tip for more efficiency

Digital HACCP solutions such as TEMPASCAN help companies to minimize typical sources of error. Thanks to automated checklists and digital documentation, the administrative workload is reduced. At the same time, companies optimize their processes and increase transparency and safety.

Interested in a digital HACCP solution? Find out more at:

www.tempascan.com | E-Mail: info@tempascan.com | Tel: +49 (0)30 859